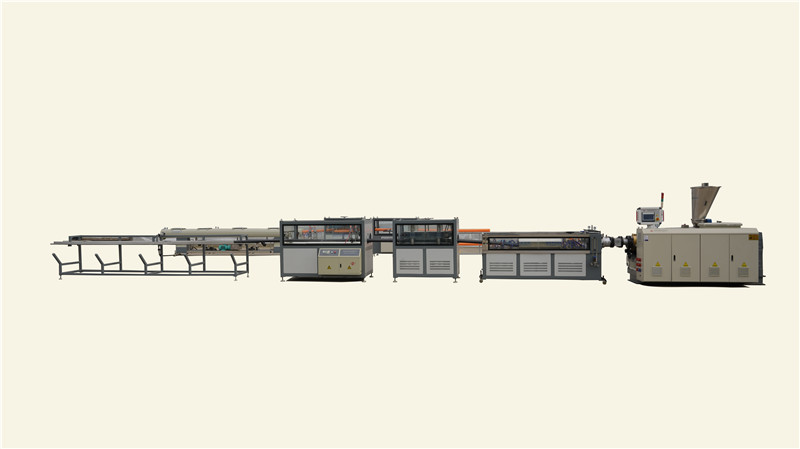

Jalur produksi pipa PVC

Detail Parameter Teknis Saben Mesin Ndhuwur

1. feeder meneng loader

| 1 | Diameter pipa beban sekrup | mm | Φ110 |

|  | ||

| 2 | Dawane pipa sekrup | mm | 4200 |

2. Conical twin meneng Extruder SJSZ80/156

3. Mould kanggo pipa PVC rong set

4, Kalibrasi Vakum lan Tank pendinginan

5. tank cooling semprotan banyu

6. Sekawan pedrails ngangkut mesin

7. Mesin pemotong planet otomatis

| Item | Katrangan | Unit | pangandikan |

| ﹡Kontrol PLC, pemotong ngitung meter otomatis, pemotongan Planetary ﹡Pneumatic clamping lan ngeculake, Pneumatic nglereni bali ﹡Saw blade nganggo carbide blade ﹡Kanthi piranti pengumpul bledug | |||

| 1 | Tipe pemotongan | mm | Nglereni otomatis |

| 2 | Dhiameter potong sing cocog | mm | 75-315 MM |

| 6 | Bahan Cutting Saw | Baja paduan | |

| 7 | Mode Clamping | Pneumatik | |

| 8 | Elemen Sistem Listrik | mm | Schneider |

| 9 | Katup saka sistem pneumatik | Saka AIR TAC | |

| 10 | LAYAR SENTUH PLC | OMRON, JEPANG | |

9. Stacker kanggo pipa rampung

Stacker

| Item | Katrangan | |

| ||

| 1 | Mode miring | Pneumatik nyopir kanthi otomatis |

| 2 | Mode kontrol | Otomatis dening sensor |

| 3 | dawa | 4000 mm |

| 10SHRL 500/1000 kacepetan dhuwur / mixer coolingsiji set | |||

Mesin Screw Loader (ngirim bahan menyang mixer panas) | |||

|

Pemanas mixer

| daya motor | kw | 75 |

| Tutup boiler | siji set digawe saka wesi | ||

| Badan boiler | siji set digawe saka stainless steel | ||

| Wektu nyawiji | Min | 8-15 | |

| Lodikula &papan panuntun | siji set | ||

| tank udara | siji set | ||

| Suhu kerja | ≤150 ℃ | ||

| Sistem obah udara | siji set | ||

| INVERTER | 75KW | ||

| MEREK BALIKAN | MADE IN CHINA | ||

| Max metu sijine | Kg/jam | 720-920kg / jam | |

| |||

| Mixer cooling | Total daya motor | kw | 11 |

| Badan boiler | siji set digawe saka stainless steel | ||

| Lodicules banyu ngubengi cooling | siji set digawe saka stainless steel | ||

| Tekanan banyu mlaku | Mpa | ≥0.1 | |

| Set kontrol peralatan listrik | siji set | ||

| Platform kontrol | siji unit dilas dening baja | ||

| Volume mixer kadhemen | 1000L | ||

| Model Reducer | WPO175 1:20 | ||

| Max metu sijine | Kg/jam | 720-920kg / jam | |

| |||

11. Mesin lonceng pipa PVCOtomatis lengkap

| Parameter teknis: |

| l Model: SGK-315 |

| l Aplikasi ranger (mm): 75-315mm |

| l Dhuwur sumbu (mm): 1000-190 |

| l Cepet ngangkut motor (KW): 1.1 |

| l Daya motor angkat (KW): 1.1 |

| PLC XINJIE UTAWA CHINA BRAND |

| Teks merek terkenal china |

| Meter kontrol suhu merek terkenal china |

| l Photoelectric ngalih account misuwur saka china |

| l Air-break ngalih Delixi |

| l Kontaktor Schneider saka Prancis |

| l Komponen pneumatik: bran misuwur saka china |

| l Air silinder: China lan Italia joint venture |

12. 600 PVC pulvertizerwww.cuishimachine.com www.cuishiextruder.com

1, Miturut padha karo karya panas: sawise nindakake karya saben jam menyang 860 kcal panas, mesin iki exhaust external, volume online gedhe, dening impor lan ekspor saka prabédan suhu angin atas jenenge paling panas, a bagean cilik saka panas wis ditanggulangi dening cooling banyu.Requirements: Suhu inlet banyu cooling ora luwih saka 25, suhu banyu stopkontak ora luwih saka 50, lan aliran banyu cooling jumbuh tambah ing mangsa panas kanggo ngurangi suhu.

13. SWP630 PVC Pipe Crusher

Sistem kabinet listrik: Aksesoris utama yaiku Siemens utawa Schneider

- Jumlah piso obah: 6 bêsik

- Jumlah piso tetep: 4 bêsik

--- Sistem pangiriman udara:

+ Motor: 3Kw – Gendéra Abang Merk

+ Volume hopper udara stainless steel: 100 meter kubik (liter)

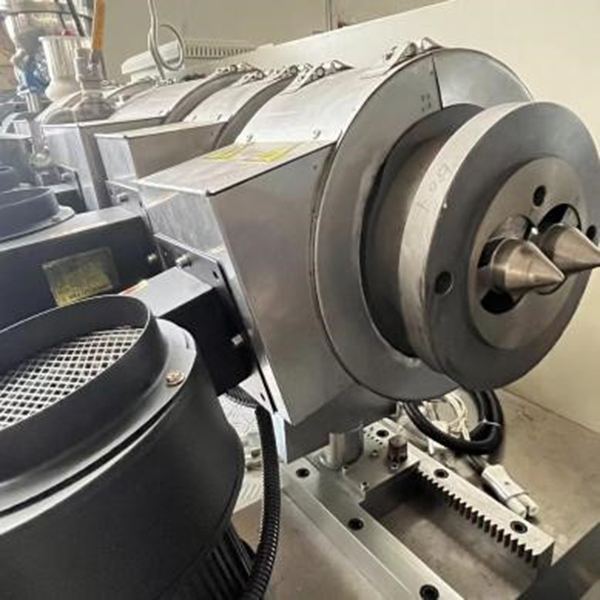

14. Mesin Pemotong Utas Pipa PVC

200-315mm Pipa otomatis mesin thread internal lan eksternal

| 1 | jinis | CS-315 |

| 2 | Diameter pipa | ¢200 mm/¢250mm/¢315 mm |

| 3 | Dawane pipa | 3m,6m |

| 4 | dhuwur tengah | 1000mm |

| 5 | Gunakake voltase | 380V, 50HZ,3 fase |

| 6 | tekanan udara terkompresi

| 0,6 Mpa |

| 7 | Total daya | 8KW |

| 8 | Motor utama | 3KW |

| 9 | Motor maju | 0,75KW |

| 10 | Daya kipas bledug | 3KW |

| 11 | Ngangkat daya motor | 0,37KW |

| 12 | imbuhan dhuwur | Pangaturan listrik ---- dening tombol |

| 13 | Warna mesin | Kanthi kabutuhan pelanggan |

| 14 | Ukuran mesin | 8370*2250*2300 |

| 15 | Bobot mesin | 2800KG |

| 16 | jinis thread | Utas njaba T-shaped lan Utas internal T-shaped |

| 17 | Bahan blade | W18Cr4V |

15 PIPE GROOVING MESIN